DOI : 10.17577/

DOI : 10.17577/In the vast world of manufacturing, have you ever wondered how some companies consistently maintain quality while predicting failures long before they happen? Enter data analytics in manufacturing—a revolution changing the way industries operate.

But what is it; how does it work; what benefit does it offer?

Let’s look into this transformative force, one thing at a time.

Statistics on Data Analytics in Manufacturing

Harnessing the power of data analytics, retailers and manufacturers fine-tuned their supply chains with precision. And it resulted in a significant reduction in inventory levels by 30%.

The Essence of Data Analytics in Manufacturing

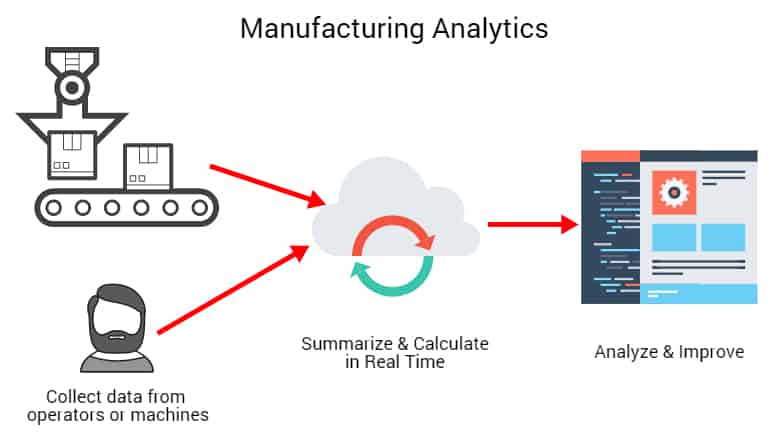

Data Analytics in manufacturing refers to the specialized application of data analysis techniques. It evaluates and interprets vast volumes of data generated within the manufacturing sector.

This analytical approach aims to improve operational efficiency, product quality, and production processes. By utilizing data analytics, manufacturers can:

- Anticipate machine failures;

- Optimize supply chains;

- Reduce waste;

- Enhance product quality.

Furthermore, it lays the groundwork for

- Informed decision-making,

- Promoting smoother operations;

- Tangible cost reductions;

- Fostering innovation.

The Role of Data Analytics in Modern Manufacturing

Today’s manufacturing world isn’t just about assembly lines and manual checks. The digital transformation wave has crashed upon the shores of this sector, making data the new leader.

Digital Transformation

Remember when ‘high-tech’ in manufacturing meant introducing a conveyor belt? Times have changed. Manufacturing is now embracing the digital age, where data isn’t just numbers; it’s the voice of every machine and product.

Predictive Maintenance

No more unexpected machine shutdowns! Through intricate algorithms and historical data, analytics can now predict when a piece of machinery is about to break down. It doesn’t just save on repair costs; it means no unexpected halts in production.

Quality Assurance

Remember the times when defects would only be discovered after a product reached the consumer? Those days are dwindling. Data analytics meticulously examines product quality at every stage. It ensures only a quality product reaches the customer.

The Benefits of Data Analytics in Manufacturing

The benefits of integrating data analytics into manufacturing include the following:

- Operational Efficiency

Imagine having a supervisor who never sleeps. One who is continually optimizing processes, minimizing waste, and streamlining workflows. That’s data analytics for you. It ensures each operational facet is optimized for peak performance.

- Easy Budgeting

With predictive analytics, costly breakdowns have become a thing of the past. But that’s not all. Data also optimize energy consumption, streamline supply chains, and reduce resource wastage. And it all leads to substantial cost savings.

- Supply Chain and Inventory Management

Gone are the days of overstocking or stockouts. Data analytics offers a peek into future demand. It ensures that warehouses are neither overflowing nor echoing with emptiness.

- Tailored Production

Fashion changes, and so do tastes. With data analytics, manufacturers aren’t just reacting to these changes but anticipating them. By analyzing market trends and customer feedback, production lines can adapt swiftly. It ensures what’s being produced is always in vogue.

- Minimized Downtime

Every second a machine sits idle, money evaporates. Data analytics does the timely diagnosing of potential issues before they become full-blown ailments. This proactive check ensures machines hum along, maximizing productive hours.

- Enhanced Employee Productivity

Data analytics gives insights into workforce productivity. It spots areas where teams may be overburdened or underutilized, allowing for timely interventions, training, or resource reallocations. The result? A motivated, efficient workforce that feels valued.

- Eco-Friendly Operations

In an age of sustainability, data analytics provides a green lens. It highlights areas where there might be unnecessary energy consumption or waste. It’s like having a sustainability coach. One who guides manufacturers on how to tread lightly on the planet while still meeting production goals.

Hurdles with Data Analytics and How to Jump Over Them

Every revolution comes with its challenges. And the data analytics revolution in manufacturing is no exception.

Data Integration

With data pouring in from various sources, integration can become a nightmare. The solution? Unified platforms that harmonize data, making it ready for analysis.

Talent Gap

The nuances of manufacturing complexities are not universally understood. A skills gap surely exists, but companies can bridge it. How? By investing in training programs or by collaborating with data analytics experts.

Security Concerns

With data’s value skyrocketing, its protection is crucial. And thus, implementing robust cybersecurity measures is non-negotiable to ward off potential breaches.

Wrapping Up

Manufacturing is no longer just about machines and workforce—it’s about the data driving them. And data analytics isn’t just a fleeting trend; it’s the future. As we stand at this intersection of machinery and data, the question isn’t whether to embrace data analytics but how swiftly you can adapt.

Whether you’re at the helm of a manufacturing giant or just setting foot in this realm, the time to harness data is now.

Dive in, explore, and let data be your north star in this manufacturing renaissance.

Author

Irene Mikhailouskaya

Irene is a Data Analytics Researcher at ScienceSoft, a global IT consulting and software development company. Covering the topic since 2017, she is an expert in business intelligence, big data analytics, data science, data visualization, and data management. Irene is a fruitful contributor to ScienceSoft’s blog, where she popularizes complex data analytics topics such as practical applications of data science, data quality management approaches, and big data implementation challenges.