DOI : 10.17577/

DOI : 10.17577/Did you know that the global quick turn PCB market is projected to reach $1.3 billion by 2025? With the demand for fast-paced electronics development on the rise, understanding what Quick Turn PCB entails is crucial for staying ahead in the industry.

The ability to rapidly prototype and manufacture printed circuit boards can significantly impact product development timelines and market competitiveness. Companies like OurPCB offer Quick Turn PCB services that can streamline your projects and drive innovation in a dynamic technological landscape.

Key Takeaways:

- Quick Turn PCBs are specialized for rapid production.

- They accelerate development and prototyping.

- Widely used in electronics, automotive, and medical industries.

- Ensure timely project completion with flexibility.

Definition of Quick Turn PCB

What exactly makes a Quick Turn PCB different from standard printed circuit boards? Quick Turn PCBs are specialized printed circuit boards that are manufactured with a rapid turnaround time compared to traditional PCBs. The key differentiator lies in their production speed, allowing for quick prototyping and production of electronic devices.

Quick Turn PCBs are ideal for situations where time is of the essence, such as in the development of new products, testing of prototypes, or urgent replacement of faulty PCBs. They’re designed to meet tight deadlines and facilitate fast iterations in the design process.

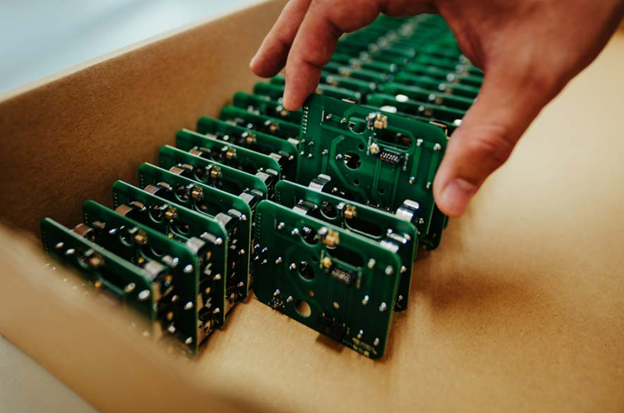

These PCBs are manufactured using streamlined processes that prioritize speed without compromising on quality. By leveraging advanced technologies and efficient workflows, manufacturers can produce Quick Turn PCBs in a fraction of the time it takes for standard PCBs. This rapid production cycle enables businesses to bring their electronic products to market faster and stay ahead of the competition.

Advantages of Quick Turn PCB

Quick Turn PCBs offer a significant advantage in accelerating the development and production of electronic devices due to their rapid turnaround time. One key benefit is the quick prototyping they allow. With Quick Turn PCBs, you can swiftly test new designs, make necessary adjustments, and iterate rapidly to achieve the desired functionality. This agility in the prototyping phase can save you valuable time in the product development cycle.

Another advantage is the fast production capability of Quick Turn PCBs. When you need electronic devices in a short amount of time, Quick Turn PCB services can deliver the required circuit boards promptly, helping you meet tight project deadlines. This speed can be crucial in staying ahead of competitors or responding promptly to market demands.

Furthermore, Quick Turn PCBs often offer flexibility in customization. Whether you require a small batch of specialized PCBs or changes to existing designs, Quick Turn services can accommodate your needs quickly and efficiently. This flexibility can be a game-changer in industries where rapid innovation is key to success.

Applications of Quick Turn PCB

To fully leverage the advantages of Quick Turn PCBs, understanding their diverse applications across various industries is essential. Quick Turn PCBs find extensive use in the electronics industry for prototyping new products and speeding up the product development cycle. They’re crucial in sectors like consumer electronics, automotive, aerospace, and medical devices where rapid prototyping and quick iterations are paramount.

In the consumer electronics industry, Quick Turn PCBs enable companies to stay ahead of trends and swiftly bring new devices to market. In the automotive sector, these fast-turnaround PCBs are instrumental in testing new vehicle technologies and improving performance. Aerospace companies rely on Quick Turn PCBs to develop cutting-edge avionics systems efficiently. Similarly, in the medical devices industry, Quick Turn PCBs aid in the rapid development of life-saving technologies.

Across industries, the agility and speed offered by Quick Turn PCBs play a vital role in innovation and staying competitive in the market.

Quick Turn PCB Process Overview

Understanding the process overview of Quick Turn PCB manufacturing is crucial for grasping the efficiency and speed it offers in prototyping and product development. The Quick Turn PCB process typically begins with the submission of the design files by the customer. These files undergo a thorough design for manufacturability (DFM) check to ensure they meet the fabrication requirements. Once approved, the PCB production kicks off with the creation of the PCB layout and the fabrication of the board.

Advanced automation tools are often employed in the assembly process to expedite production. Following assembly, rigorous quality checks are conducted to verify the functionality and reliability of the PCB. Quick Turn PCB manufacturers prioritize speed without compromising on quality, enabling rapid iteration and testing of designs.

This streamlined process allows for quick turnaround times, making Quick Turn PCBs an ideal choice for fast-paced prototyping and product development projects.

Importance of Quick Turn PCBs

For a successful PCB prototyping and product development process, recognizing the significance of Quick Turn PCB fabrication can’t be overstated. Quick Turn PCBs play a crucial role in expediting the production timeline and ensuring that your projects are completed in a timely manner. Here’s why Quick Turn PCBs are essential:

- Accelerated Time-to-Market: Quick Turn PCB fabrication allows you to reduce lead times significantly, enabling you to get your products to market faster than traditional PCB manufacturing methods.

- Rapid Prototyping: With Quick Turn PCBs, you can quickly iterate on designs and test multiple versions, facilitating a more efficient prototyping phase and ultimately leading to a superior end product.

- Flexibility and Adaptability: Quick Turn PCB services offer the flexibility to make last-minute design changes or corrections, accommodating unforeseen challenges or requirements without causing significant delays in the production process.

How Does the Cost of Quick Turn PCBs Compare to Standard PCB Manufacturing?

When comparing the cost of quick turn PCBs to standard PCB manufacturing, you’ll find that quick turn PCBs typically come at a higher price due to the expedited production process and shorter lead times.

What Factors Can Affect the Turnaround Time for Quick Turn PCB Orders?

Factors affecting the turnaround time for quick turn PCB orders include design complexity, material availability, and production queue. By optimizing these variables and clear communication with suppliers, you can expedite the manufacturing process.

Are There Any Limitations to the Complexity or Size of PCBs That Can Be Produced With Quick Turn Services?

When using quick turn services for PCB production, keep in mind that there may be limitations on complexity and size. It’s essential to check with the manufacturer beforehand to ensure your design can be accommodated.

Can Quick Turn PCBs Be Manufactured With Specific Materials or Finishes?

When manufacturing quick turn PCBs, you have the flexibility to choose specific materials or finishes based on your project needs. This allows you to customize your PCBs to meet the requirements of your design effectively.

How Does the Quality of Quick Turn PCBs Compare to Traditionally Manufactured PCBs?

When considering the quality of quick turn PCBs versus traditionally made ones, you’ll find that quick turn PCBs often offer comparable quality standards. They can meet your needs swiftly without compromising on performance or reliability.